GearBox

As one of the worm reducer manufacturers, suppliers, and exporters of mechanical products, We offer v and many other products.

Please get in touch with us for details.

High-Precision planetary gearboxes

Precision Planetary Gearbox Features

- The gear material is made of high-quality alloy steel through surface hardening treatment, and hardened gear surface hobbing is used to enhance the impact resistance of the gear, reduce gear noise, and improve the service life of the gear.

- The finite element analysis of gear strength is carried out by using ANSYS technology. At the same time, the tooth profile and lead are trimmed on the tooth surface to reduce the impact and noise of gear engagement and increase the service life of the gear train.

- The planet carrier and output shaft adopt an integrated structure design. The bearing of the output shaft adopts a large span design to ensure the maximum torsional rigidity and output load force. The one-time processing technology is used to improve the precision and rigidity of the output shaft and the overall planet carrier

- The box body and internal gear are designed and manufactured in an integrated way. The box body is made of high-quality steel. Through the hot forging process, it has higher strength and toughness, which further improves the accuracy and strength of internal gear.

- The connection between the input end and the motor adopts a simple clamp type locking mechanism, and the dynamic balance analysis is carried out. To ensure the power transmission of concentricity and zero backlash at the connection under high input speed.

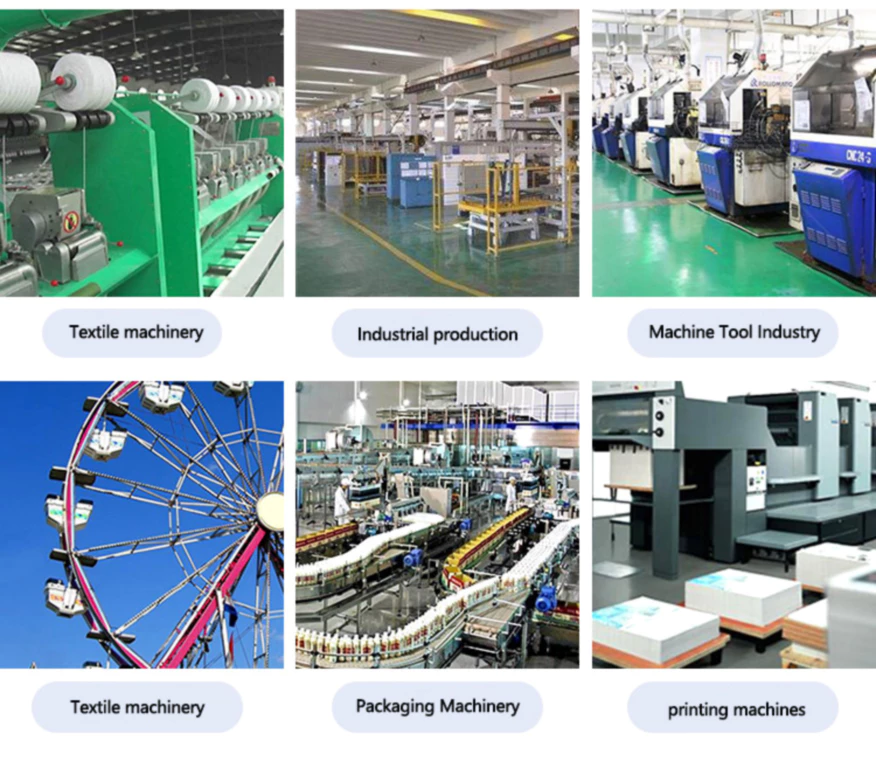

Precision planetary gearbox Application

Precision planetary gear reducer is widely used in the following fields:

1 aerospace, military industry,

2 medical and health, electronic information technology industry,

3 industrial robots, production automation, CNC machine tool manufacturing industry,

4 automobile manufacturing, textile, printing, food, metallurgy, environmental protection engineering, warehousing and logistics industries.

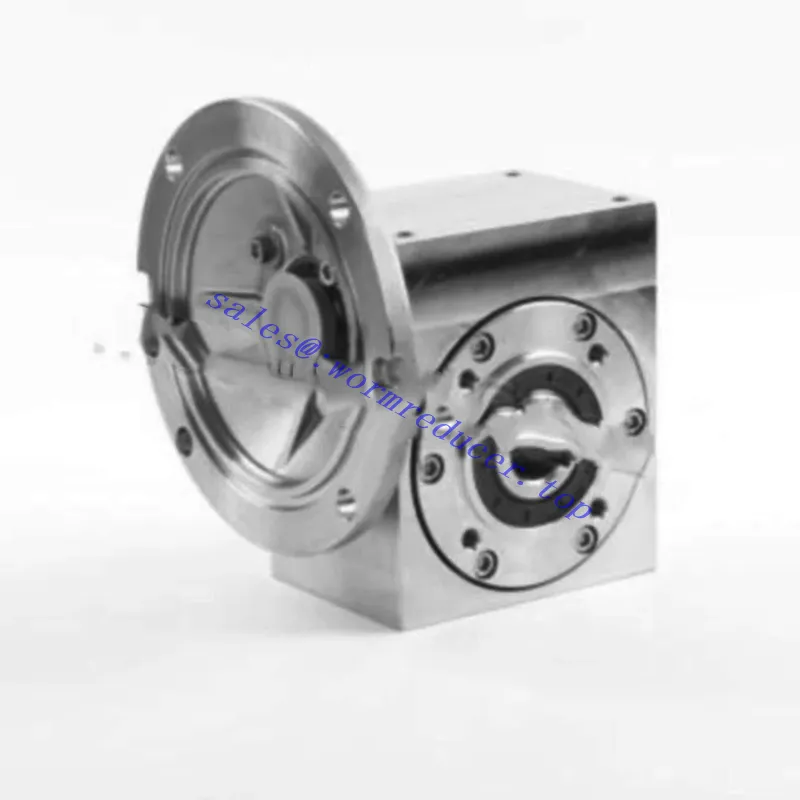

Stainless Steel Worm Gear Reducer

Stainless steel worm gear reducers are commonly found in food industry. Food safe series motor or worm geared motors are particularly suited for the meat, poultry, fish and dairy industries where severe contamination can occur. They can reduce a wide variety of speeds and torques. These stainless steel worm gearboxes can be custom-designed to meet specific needs. If you’re looking for a stainless steel worm gear reducer for your particular application, you can trust us. We are committed to mechanical transmission and can provide custom solutions for your particular needs.

Stainless steel worm gear reducers are commonly found in the food industry. Food safe series motor or worm geared motors are particularly suited for the meat, poultry, fish and dairy industries where severe contamination can occur. They can reduce a wide variety of speeds and torques. These gearboxes have a maximum speed reduction ratio of six to one. In addition, they can be custom-designed to meet your specific needs. If you're looking for a stainless steel worm gear reducer for the particular application, we can help. As a leading manufacturer of speed reducer gearbox, we are committed to mechanical transmission and can provide custom solutions for your particular needs.

The worm is a gear with teeth and the gears have different shapes to increase the capacity of the reducer. The axial pitch and circular pitch are the distance between the points of the teeth on the worm. The threads of the worm can have left-hand or right-hand threads. The lead refers to the distance that a certain point on the thread will travel over the revolution of the worm. The lead angle is the angle that the helix of the thread tangents to the pitch of the cylinder.

Stainless Steel Gear Motors

We introduces a full line of stainless steel IEC food safety motors fitted with the stainless steel worm gear reducers designed for harsh washdown conditions in industries where sanitation is critical. The Food Safety series motors or worm gear motors are particularly suitable for the meat, poultry, fish and dairy industries where severe contamination can occur.

To reduce the risk of contamination and the amount of water and chemicals required to sanitize equipment, all food safety products involved need to be easy to clean. The stainless steel motors feature smooth, rounded housings that eliminate gaps that could trap food particles and harbor bacteria. Even the nameplates on motors and gears are laser etched to avoid channels and ridges where contaminants can accumulate.

The entire food safe range is designed with an advanced sealing system that has achieved an IP69 waterproof rating - the benchmark for products used in the sanitary sector. This classification means these products can withstand cleaning by high-pressure water jets commonly used in cleaning-in-place (CIP) procedures. The all stainless steel construction protects against corrosion.

The stainless steel safety motors and worm gear reducers feature encapsulated windings for longer life in harsh washdown conditions than general purpose products. These motors also eliminate the need for a motor shroud that can contain food particles and allow bacteria to colonize. They are available in power ranges from 0.18-7.5 kw in 2-6 pole versions for 230-690 volts, 50 or 60 Hz.

Features of Stainless Steel Worm Gear Reducers and Motors

- Smooth stainless steel housing for easy cleaning and disinfection

- IP69 waterproof rating ensures in-place cleaning procedures

- Laser engraved nameplate eliminates contaminants from underneath traditional nameplates

- Encapsulated windings prevent any water and moisture from reaching the windings

- Low operating costs due to high efficiency and low surface temperatures

- H1 food grade synthetic grease

- Motors with a power range of 0.18 - 7.5 kW, 2-6 poles, 230-690 V, 50 and 60 Hz.

Why Choose Stainless Steel Worm Gear Reducers

This type of worm speed reducer features a stainless steel body and is the industry leader in worm gear technology. These stainless steel worm-gear speed reducers provide the highest corrosion resistance and are ideal for high-pressure applications like food and beverage processing. Their modular design allows for ease of installation and maintenance, while the large oil reservoir helps to ensure proper lubrication and heat dissipation. They also offer multiple mounting positions for a wide range of applications. The housings are straddle-milled for precise alignment, and internal baffles ensure positive venting.

The Stainless Steel worm gear reducers We provides are made from high-strength, case-hardened alloy steel. While it may be slightly more expensive than painted gearboxes, the corrosion-resistant materials

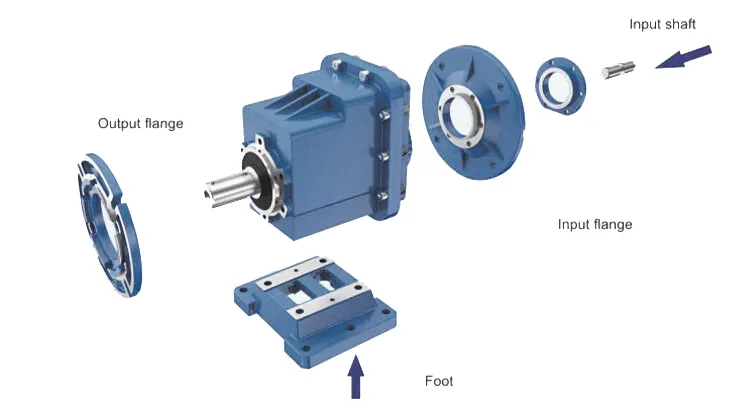

RC Series Helical Gearbox

| Housing: | Aluminum Alloys |

| Gears: | Hardened Helical Gears |

| Input Configurations: | Hollow Shaft with IEC Normalized Motor Flange Solid Shaft Input |

| Applicable Motors: | IEC-normalized Motors and Brake Motors Explosion-proof Motors Inverter Motors Servo Motors |

| Output Configurations: | Solid Shaft with B5 Output Flange Solid Shaft with B14 Output Flange |

| Models: | RC(Foot-mounted): RC01,RC02,RC03,RC04 RCF(B5 Flange-mounted): RCF01,RCF02,RCF03,RCF04 RCZ(B14 Flange-mounted): RCZ01,RCZ02,RCZ03,RCZ04 |

| Installation: | Foot-mounted B5 Flange-mounted B14 Flange-mounted |

| Lubrication: | Oil-bath and Splash Lubrication |

| Cooling: | Natural Cooling |

RC Series Helical Gearbox

RC series helical gearbox is a new generation product designed based on the modular system, and It can be connected respectively with motors such as IEC standard motor, brake motor, explosion-proof motor, frequency motor, servo motor, and so on. it has 4 types(01-02-03-04),power from 0.12kw to 4.0kw, ratio from 3.66 to 58.09, Max torque from 120Nm to 500Nm.It can be connected discretionary(foot or flange) and use multi-mounting positions accordingly. RC series helical gearbox is widely used in textile, foodstuff, beverage, tobacco, logistics, industrial fields, etc.

RC Series Helical Gearbox Features:

1. Modular design, dismountable frame foot, optional different frame sizes and flanges

2. Aluminum housing, compact structures, light weight

3. Carburizing and grinding hardened gears, sturdy and durable

4. Multiple mounting positions

5. Low noise

RC Series Helical Gearbox Applications:

RC series helical gearbox own rational design, compact construction, smaller size than X or B series cycloidal gearmotor at the same permitted torque. RC series helical gearbox is widely used in the textile, food, ceramics, packaging, logistics, and plastics industry.

We are one of the best gearbox manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application