Durable Using 0.06-15W 1400RPM Speed Reducer Pull Back Gearbox Worm Gearbox

As one of the worm reducer manufacturers, suppliers, and exporters of mechanical products, We offer v and many other products.

Please get in touch with us for details.

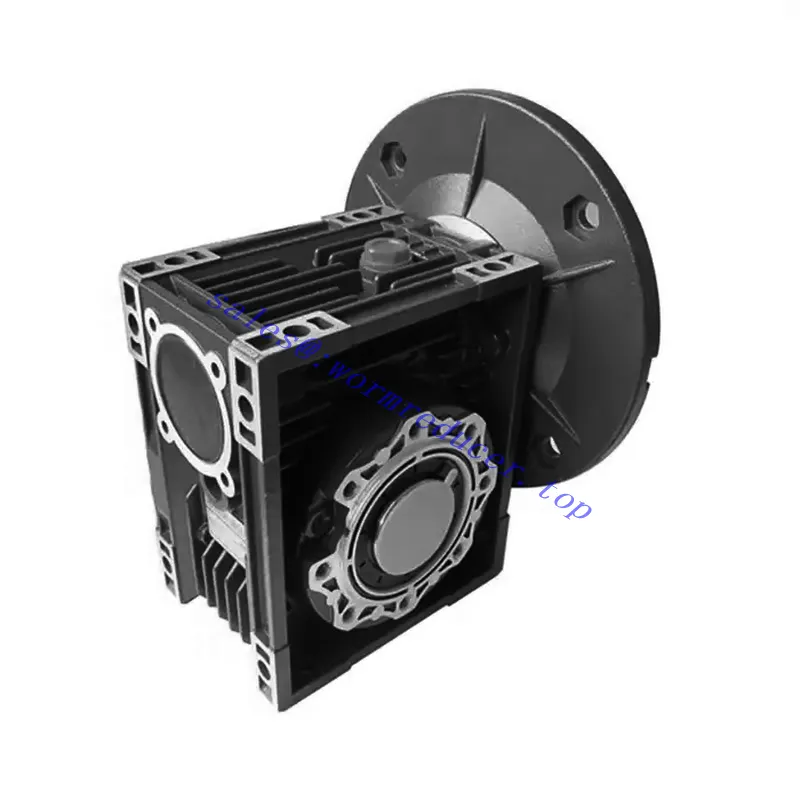

Worm Reducer

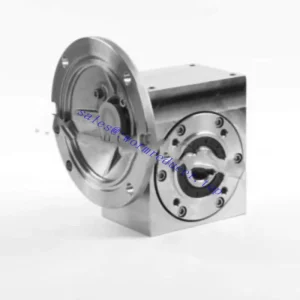

With the stainless steel worm reducer, you can unlock unparalleled performance and precision in your industrial applications. This reducer is meticulously crafted using high-quality materials and advanced manufacturing techniques, ensuring exceptional strength and durability. Its robust construction and corrosion-resistant stainless steel body make it capable of withstanding the harshest environments, providing reliable and consistent operation over the long term.

Durability is paramount when it comes to industrial machinery, and the stainless steel worm reducer delivers on that front. Its rugged design and high-quality components are built to withstand heavy loads, extreme temperatures, and harsh working conditions. With this reducer, you can have peace of mind knowing that your machinery will continue to perform optimally, minimizing downtime and maximizing productivity.

Efficiency is key in any industrial setting, and the stainless steel worm reducer is designed to optimize power transmission and minimize energy loss. Its innovative gear system ensures smooth and accurate motion control, providing precise speed reduction and torque multiplication. This enables your machinery to operate at its full potential, resulting in higher productivity and reduced operating costs.

Worm Reducer Specifications

|

Worm

|

20Cr, carburized and quenched, tooth surface hardness 58-62HRC, keep carburized layer thickness 0.3-0.5mm after fine grinding

|

|

Case Material

|

aluminum alloy (frame: 030-090). Cast iron (frame: 110-130)

|

|

worm gear

|

Wear resistant nickel bronze

|

|

treatment

|

Shot blasting treatment is followed by special anticorrosion treatment to maintain silver and white metallic feeling and resist

the corrosion of organic solvents such as gasoline and xylene; |

Worm Reducer Benefits

Enhanced Performance: The worm reducer is designed to optimize power transmission, ensuring smooth and accurate motion control. With its precise gear system and reduction ratios, it enables your machinery to operate at its full potential, resulting in improved performance and productivity.

Increased Efficiency: By minimizing energy loss during power transmission, the stainless steel worm reducer helps you achieve optimal efficiency in your machinery. This not only reduces operating costs but also enhances overall productivity by maximizing the output for a given input.

Reliable and Durable: Built with premium-grade stainless steel, this reducer boasts exceptional durability and reliability. It can withstand heavy loads, harsh environments, and demanding operating conditions, providing you with a long-lasting solution that minimizes downtime and maintenance costs.

Versatility and Adaptability: The worm reducer offers versatile mounting options and a range of input and output configurations to suit various machinery setups. This adaptability allows for seamless integration into your existing systems, ensuring compatibility and ease of installation.

Precise Speed Control: With the ability to customize the reduction ratio, the worm reducer enables precise control over speed and torque output. This is particularly advantageous when dealing with applications that require specific speed adjustments or torque multiplication.

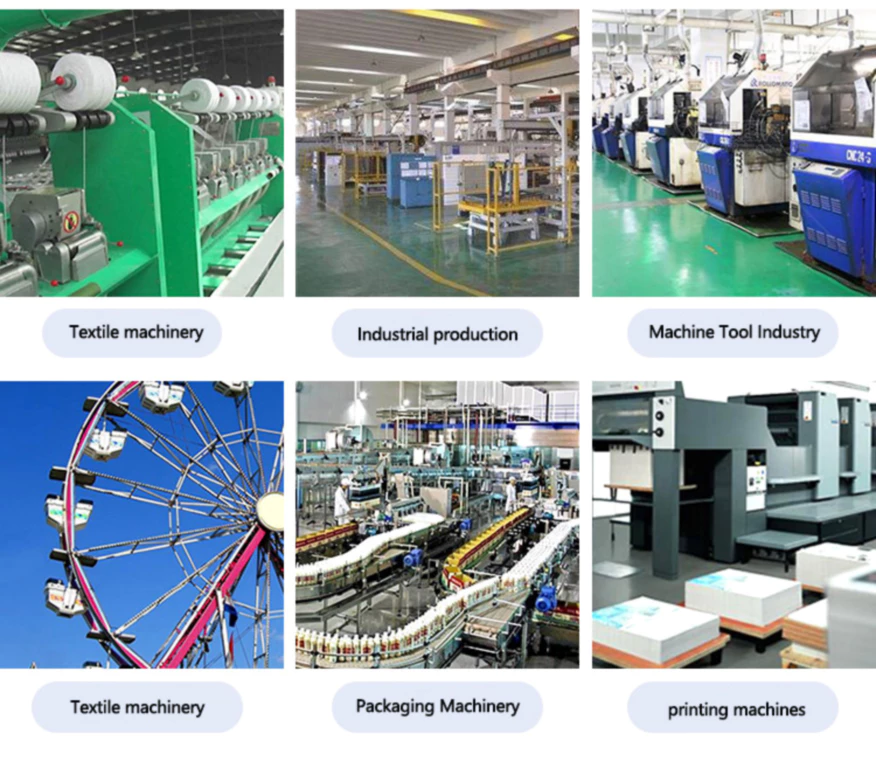

Uses Of Worm Reducer

1. Conveyor Systems: Worm reducers are commonly used in conveyor systems to control the speed and torque of the conveyor belts. They enable smooth and precise movement of materials, ensuring efficient transportation in industries such as manufacturing, logistics, and warehousing.

2. Packaging Equipment: Worm reducers play a crucial role in packaging machinery, including filling machines, labeling machines, and sealing machines. By providing precise speed control and torque multiplication, they ensure accurate and consistent packaging processes.

3. Mixers and Agitators: Worm reducers are employed in mixers and agitators used in industries like food processing, chemical manufacturing, and pharmaceuticals. They enable efficient and controlled mixing of ingredients, ensuring consistent product quality.

4. Material Handling Equipment: Forklifts, cranes, and hoists often utilize worm reducers to control the lifting and lowering of heavy loads. The reducers provide the necessary torque and speed control for safe and efficient material handling operations.

5. Industrial Machinery: Worm reducers are widely used in various industrial machinery applications, including rotary tables, machine tools, and printing presses. They facilitate precise motion control, ensuring accurate positioning and operation of the equipment.

6. Food Processing Equipment: In the food industry, worm reducers are employed in a range of equipment such as dough mixers, meat grinders, and slicers. They provide the necessary power and control for efficient processing and handling of food products.

Maintenance tips for Worm Reducer

1. Regular Inspection: Perform routine visual inspections of the worm reducer to check for any signs of wear, damage, or leaks. Look for loose bolts, cracks, oil leakage, or abnormal noise during operation. Promptly address any issues identified during inspections.

2. Lubrication: Proper lubrication is crucial for the smooth operation and longevity of the worm reducer. Follow the manufacturer's guidelines for lubrication intervals and use the recommended lubricant. Ensure that the lubricant levels are maintained within the specified range.

3. Lubricant Replacement: Regularly replace the lubricant based on the manufacturer's recommendations. Over time, lubricants can break down or become contaminated, leading to decreased performance. Clean the gear surfaces before adding fresh lubricant.

4. Seal Inspection: Check the seals and gaskets of the worm reducer for signs of wear or damage. Replace any worn-out seals to prevent contaminants from entering the gearbox and to maintain proper lubrication.

5. Bolt Tightening: Ensure that all bolts and fasteners are properly tightened. Vibration and operational stresses can cause bolts to loosen over time, leading to misalignment and potential damage. Regularly check and tighten any loose bolts, following the manufacturer's specifications.

6. Temperature Monitoring: Monitor the operating temperature of the worm reducer. Excessive heat can indicate a problem with lubrication or overloading. If the temperature exceeds the recommended range, investigate and address the underlying cause.

We are one of the best worm reducer manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application