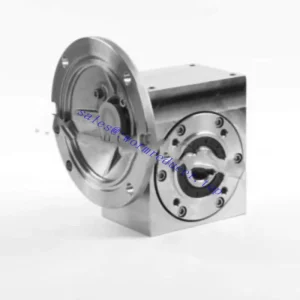

Worm Reducer

HIGH QUALITY HIGH PRECISE MANUFACTURER & SUPPLIER

What Is A Worm Reducer?

A worm reducer, also known as a worm gear reducer or worm gearbox, is a type of power transmission device used to control speed and torque in machinery and equipment. It consists of two main components: a worm gear (also called a worm screw) and a worm wheel (also known as a worm gear wheel).

The worm gear is a threaded cylindrical gear with one or more teeth, called threads, wrapped around its circumference. The worm wheel, on the other hand, is a toothed wheel that meshes with the worm gear. The arrangement of the teeth on the worm gear and worm wheel is such that the motion is transmitted from the worm gear to the worm wheel in a single direction.

The key characteristic of a worm reducer is its ability to provide a high reduction ratio, meaning it can significantly reduce the speed of rotation while increasing the torque output. This is achieved through the interaction of the helical threads on the worm gear and the teeth on the worm wheel. As the worm gear rotates, it engages and drives the worm wheel, resulting in the desired speed reduction and torque multiplication.

How To Maintain The Worm Reducer?

Here are some key steps to follow for effective maintenance of a worm reducer:

Regular Inspections: Perform routine visual inspections of the worm reducer to identify any signs of wear, damage, or leaks.

Lubrication: Proper lubrication is essential for the smooth operation of the worm reducer.

Lubricant Replacement: Over time, lubricants can break down or become contaminated, leading to decreased performance. Clean the gear surfaces before adding fresh lubricant.

Seal Inspection: Check the seals and gaskets of the worm reducer for signs of wear or damage.

Bolt Tightening: Ensure that all bolts and fasteners are properly tightened.

Temperature Monitoring: Monitor the operating temperature of the worm reducer.

Worm Reducer For Sale

Worm Reducer Advantage

High Reduction Ratio

Worm reducers provide a high reduction ratio, allowing for significant speed reduction while increasing torque output.

Compact Design

Worm reducers have a compact design, which makes them space-efficient and allows for easy integration into different systems and machinery.

Self-Locking

One significant advantage of worm reducers is their inherent self-locking property. When the worm gear is not in motion or under load, the friction between the worm gear and worm wheel prevents the output shaft from rotating.

Years

Products

Client

Application of Worm Reducer

Conveyor Systems

Worm reducers are commonly employed in conveyor systems to control the speed of the conveyor belt or other conveying mechanisms. They provide the necessary torque to move heavy loads and ensure smooth and controlled material handling.

Lifting and Hoisting Equipment

Worm reducers are used in lifting and hoisting equipment such as cranes, winches, and elevators. They enable controlled lifting and lowering of heavy loads by providing high torque output and precise speed control.

Mixers and Agitators

Worm reducers are utilized in mixers and agitators found in industries such as food processing, chemical processing, and pharmaceuticals. They enable the mixing and agitation of materials by providing the required torque and controlling the rotational speed of the mixing blades or paddles.

Packaging Machinery

Worm reducers are incorporated into packaging machinery, including filling machines, capping machines, and labeling equipment. They help control the speed and torque required for precise packaging operations.

What Is The Working Principle Of Worm Reducer?

The working principle of a worm reducer is based on the interaction between a worm gear (worm screw) and a worm wheel (worm gear wheel). The worm gear is a threaded cylindrical gear with one or more teeth, called threads, wrapped around its circumference. The worm wheel, on the other hand, is a toothed wheel that meshes with the worm gear.

When power is supplied to the input shaft connected to the worm gear, it starts rotating. As the worm gear rotates, its threads engage with the teeth of the worm wheel. The helical shape of the threads on the worm gear causes the worm wheel to rotate as well.

The key characteristic of a worm reducer is the directionality of the motion transmission. The worm gear can drive the worm wheel, but the reverse is not true. This is because the angle of the helical threads on the worm gear is designed to create a locking effect, preventing the worm wheel from driving the worm gear.